Valves & Actuators

The SSV is the device that blocks or allows the flow thru the production line. It is therefore an essential part of the Surface Safety System. It´s components are a Model “S” gate valve plus an actuator. The combination of the Model “S” gate valve with an inverted port gate (the opening port is in the upper section of the gate) and the MMA actuator, results in the SSV to be normally closed.

The model S valve can be supplied with pneumatic or hydraulic actuators.

The pneumatic or hydraulic operated valves, meet a wide range of applications in oil and gas services up to 10,000 PSI, they can be supplied with pilots, filters and all the necessary elements that compose and integrated surface safety system.

The model S valve can be supplied with pneumatic or hydraulic actuators.

The pneumatic or hydraulic operated valves, meet a wide range of applications in oil and gas services up to 10,000 PSI, they can be supplied with pilots, filters and all the necessary elements that compose and integrated surface safety system.

In case of hydraulic operated valves, they can be supplied as self-contained packages. These units do not require external power source.

Actuator´s main feactures are to have Internal sleeve protected with Non Electrolytic Nickel Coating, non elastomeric stem packing, Metal to Metal backseat be-tween stem & bonnet, adjustable built-in stroke limit and to be easy inspection and repairing.

Actuator´s main feactures are to have Internal sleeve protected with Non Electrolytic Nickel Coating, non elastomeric stem packing, Metal to Metal backseat be-tween stem & bonnet, adjustable built-in stroke limit and to be easy inspection and repairing.

Model NL17 Pneumatic Valve with low pressure Actuator

Model NV12 Pneumatic Actuated valve with manual override

Pneumatic Actuators:

The MMA pneumatic actuators are simple effect piston actuators designed to operate any gate valve, not just the MMA. These actuators can be powered

Main Features:

Main Features:

- Internal sleeve protected with Non Electrolytic Nickel coating.

- NON elastomeric stem packing.

- Metal to Metal backseat between stem & bonnet.

Hydraulic Actuators:

The MMA hydraulic actuators are simple effect piston actuators designed to operate any gate valve, not just the MMA. These actuators can be powered by standard hydraulic oils.

Main Features:

Main Features:

- Internal sleeve protected with Non Electrolytic Nickel Coating.

- NON elastomeric stem packing.

- Metal to Metal backseat between stem & bonnet.

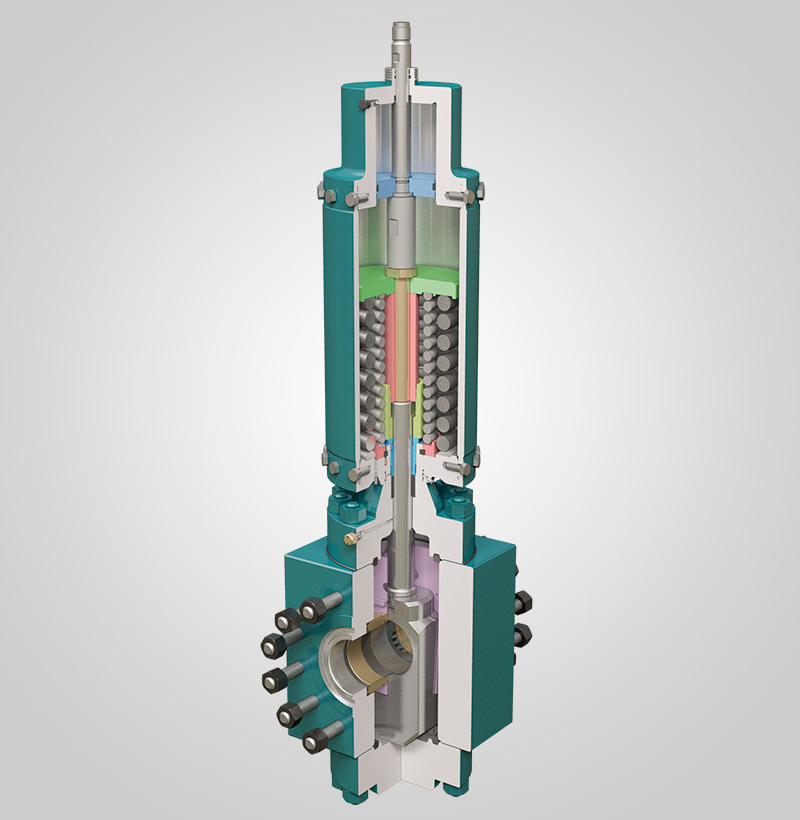

Model HDA Surface Safety Frac Valve

Model T-10 HDA & T-15 HDA API 6A Gate Valves are frac valves with a double acting hydraulic actuator.

The double acting piston Hydraulic actuator allows the valve to be controled fast and remotely by means of a compact control panel connected at distance.

In case of not having an hydraulic pressure source, the valve has a manual override system handwheel with recirculating balls in order to open or close the valve with no excessive torque needed.

The double acting piston Hydraulic actuator allows the valve to be controled fast and remotely by means of a compact control panel connected at distance.

In case of not having an hydraulic pressure source, the valve has a manual override system handwheel with recirculating balls in order to open or close the valve with no excessive torque needed.

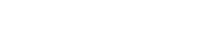

Model H9-WLC SSV Valve

Model S10 API 6A gate valve with model H9-300 WLC hydraulic actuator is mainly used in wireline operations.

It works as a conventional actuator, it closes automatically at pressure control lost and will open automatically when control pressure is restaured under normal production and becomes the main surface safety device during wireline operations to ensure wireline cutting and well flow sealing in case of emergency.

This is possible because two power springs located in H9-300 WLC actuator which aplies much strenght to cut the wire.

It works as a conventional actuator, it closes automatically at pressure control lost and will open automatically when control pressure is restaured under normal production and becomes the main surface safety device during wireline operations to ensure wireline cutting and well flow sealing in case of emergency.

This is possible because two power springs located in H9-300 WLC actuator which aplies much strenght to cut the wire.