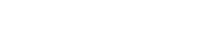

Innovation in overpressure protection (HIPPS)

High Integrity Pressure Protection Systems (HIPPS) are used to reduce the risk of a system exceeding its design pressure.

HIPPS is designed specifically to protect personnel and downstream equipment. It prevents over-pressurizing by closing a specific valve that blocks the pressure source. Resulting in significant cost savings because is not required for downstream equipment to cope with an unmitigated upstream incident.

STANDARD IN SECURITY WITH HIPPS

To help manage the increasing and unprecedented risks, the concepts of Safety Instrumented Systems (SIS) and Safety Integrity Levels (SIL) were created and applied. A HIPPS is a specific type of SIS. SIS consists of hardware and software controls designed specifically to take a critical process system into a safe mode in the event of an operational problem avoiding adverse safety, health and environmental consequences.

Con HIPPS, la protección contra la sobrepresión se consigue reduciendo a un nivel tolerable el riesgo de que la presión pueda exceder un determinado nivel máximo. El diseño de HIPPS se rige por las normas IEC 61508, IEC 61511 y ANSI / ISA S84.01.

ADVANTAGES::

• Standalone assembly.

• Simpler & independent operation.

• No electrical wiring.

• Integrated pressure sensing / logic solver.

• No need for auxiliary systems or power sources.

• Simple maintenance.

• Lower TCO (Total Cost of Ownership).

Mechanical HIPPS guarantee cost-effective, reliable pressure protection. Conventional HIPPS for emergency shutdown rely on complex electronics and instrumentation while issues related to the reliability of these components and costs have restricted their use.

The development of a mechanical HIPPS addresses some of the issues associated with conventional instrumented HIPPS.

WHERE IS HIPPS USED?

As oil and gas resources become harder to find, producers are forced to operate in environments of great risk and the consequences of catastrophic failure to

personnel, the environment and infrastructure are important.

Conventional design standards applied in the oil and gas industry stipulate that final protection of piping and pressure vessels against over-pressurization should be provided by mechanical relief devices. Sometimes the use of these devices, like relief valves, is undesirable or impossible. HIPPS provide a technically solid and economically more attractive solution to this problem.

HIPPS is designed specifically to protect personnel and downstream equipment. It prevents over-pressurizing by closing a specific valve that blocks the pressure source. Resulting in significant cost savings because is not required for downstream equipment to cope with an unmitigated upstream incident.

STANDARD IN SECURITY WITH HIPPS

To help manage the increasing and unprecedented risks, the concepts of Safety Instrumented Systems (SIS) and Safety Integrity Levels (SIL) were created and applied. A HIPPS is a specific type of SIS. SIS consists of hardware and software controls designed specifically to take a critical process system into a safe mode in the event of an operational problem avoiding adverse safety, health and environmental consequences.

Con HIPPS, la protección contra la sobrepresión se consigue reduciendo a un nivel tolerable el riesgo de que la presión pueda exceder un determinado nivel máximo. El diseño de HIPPS se rige por las normas IEC 61508, IEC 61511 y ANSI / ISA S84.01.

ADVANTAGES::

• Standalone assembly.

• Simpler & independent operation.

• No electrical wiring.

• Integrated pressure sensing / logic solver.

• No need for auxiliary systems or power sources.

• Simple maintenance.

• Lower TCO (Total Cost of Ownership).

Mechanical HIPPS guarantee cost-effective, reliable pressure protection. Conventional HIPPS for emergency shutdown rely on complex electronics and instrumentation while issues related to the reliability of these components and costs have restricted their use.

The development of a mechanical HIPPS addresses some of the issues associated with conventional instrumented HIPPS.

WHERE IS HIPPS USED?

As oil and gas resources become harder to find, producers are forced to operate in environments of great risk and the consequences of catastrophic failure to

personnel, the environment and infrastructure are important.

Conventional design standards applied in the oil and gas industry stipulate that final protection of piping and pressure vessels against over-pressurization should be provided by mechanical relief devices. Sometimes the use of these devices, like relief valves, is undesirable or impossible. HIPPS provide a technically solid and economically more attractive solution to this problem.